Dog Food Machine

Dog Food Machine

Dog Food Machine video

|

Demand table loading...

|

Dog Food Machine Description

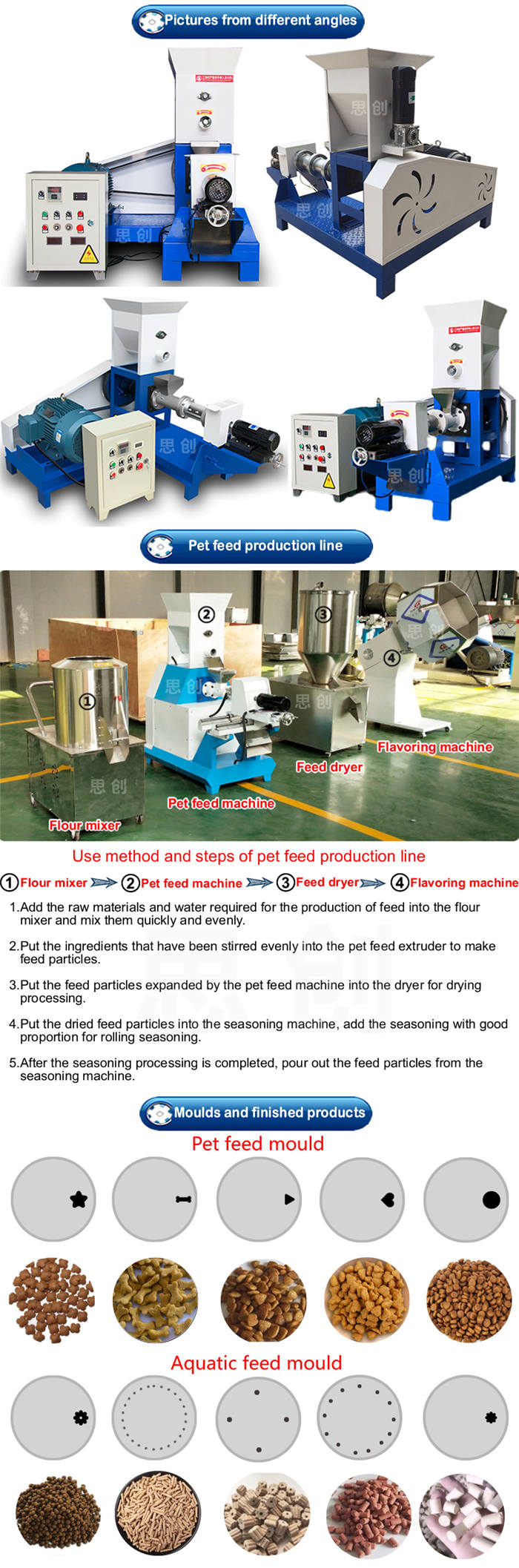

Operation Method Of Dog Food Machine Production Line:

1.Add the raw materials and water required for the production of feed into the flour mixer and mix them quickly and evenly.

2.Put the ingredients that have been stirred evenly into the pet feed extruder to make feed particles.

3.Put the feed particles expanded by the pet feed machine into the dryer for drying processing.

4.Put the dried feed particles into the seasoning machine, add the seasoning with good proportion for rolling seasoning.

5.After the seasoning processing is completed, pour out the feed particles from the seasoning machine.

Instructions for pellet puffing feed machine:

1. The granule puffer is suitable for raising fish, shrimp, frogs, pigs, ducks, etc. The expanded feed produced by the extruder has the right to expand, soft cooked, high protein, complete nutritional components, floating on the water for a long time, and does not waste feed. Add trace elements to promote the rapid growth of fish.

2. Add wheat skin, corn flour, bean cypress, fish meal, etc. with composite premix, add 10-17 kg of water per 100 kg according to the formula, put it into the mixer and mix evenly, about 3-5 minutes, start the mixer auger, pump the material into the savings bucket, and then draw it into the mouth of Penghua machine by the savings bucket auger. Pay attention to control the closing of the storage barrel. From small to large.

3, cut the grain part, the size of the cut is determined by the grain hole. If you want to Peng Hua in general 4.5 centimeters, Confucius open 4-5, if you want to produce high, do not Peng Hua can open 10-15 holes, small motor can be adjusted before and after, the knife is in the right direction, when the material is cut, it is best to start with 3-5 Jin of feed and more water.

4. After the first feeding, disassemble the cutting part of the front section, immediately disassemble the nut on the extruder head with a tool hook, then start the motor to flow out the excess feed in the machine and clean the nut orifice.

Common faults and maintenance methods of pet feed machine:

1. There are strange noises in the machine body, the bearings are rotten, worn and lack of oil. Maintenance method: disassemble the large pulley, discharge the front part, and hammer out the main shaft later. Insert the rear bearing first, fix the rear cover screws, and then enter the front bearing. Replace the oil seal, add lubricating oil, and do not add engine oil.

2. The screw (propeller) can generally produce about 100000 kg, which will wear, reduce the output and do not expand. Treatment: replace with a new screw (propeller) sleeve, which is more durable than the propeller. Generally, the new propeller is equipped with the old sleeve, and the new sleeve is equipped with the old shaft (propeller).

|

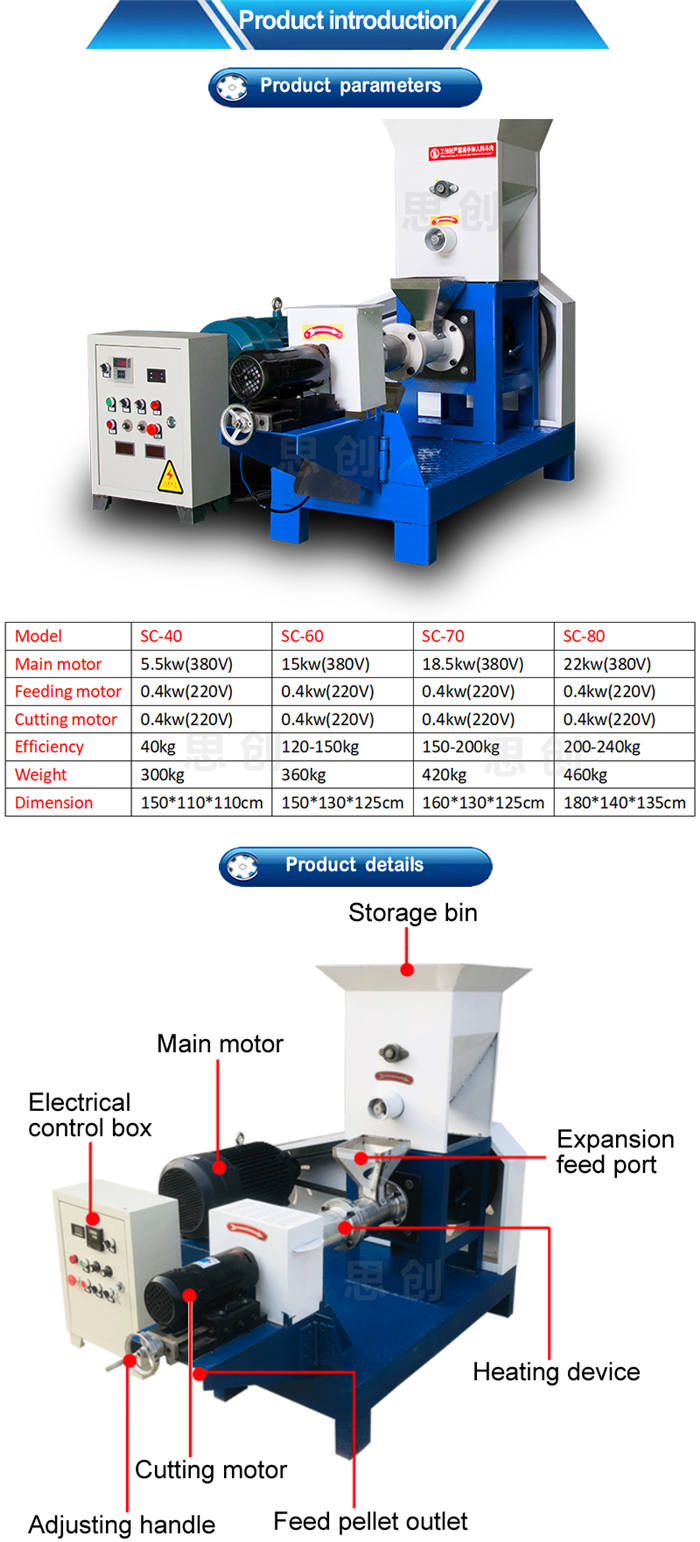

Model |

SC-40 |

SC-60 |

SC-70 |

SC-80 |

|

Main motor |

5.5kw(380V) |

15kw(380V) |

18.5kw(380V) |

22kw(380V) |

|

Feeding motor |

0.4kw(220V) |

0.4kw(220V) |

0.4kw(220V) |

0.4kw(220V) |

|

Cutting motor |

0.4kw(220V) |

0.4kw(220V) |

0.4kw(220V) |

0.4kw(220V) |

|

Efficiency |

40kg |

120-150kg |

150-200kg |

200-240kg |

|

Weight |

300kg |

360kg |

420kg |

460kg |

|

Dimension |

150*110*110cm |

150*130*125cm |

160*130*125cm |

180*140*135cm |

Dog Food Machine News

- 2023-02-01 How To Make Dog Food With Domestic Dog Food Machine

- 2022-11-01 Preparation Before Starting Dog Food Machine

- 2022-08-23 Research And Development Background Of Dog Food Machine

- 2022-07-13 Dog Food Machine Is A Multi-functional Puffing Machine

- 2022-04-09 How Does The Dog Food Machine Work

- 2022-02-03 Dog Food Machine Made In China At Best Price

- 2022-01-19 Instructions For Pellet Puffing Feed Dog Food Machine

- 2022-01-19 Common Faults And Maintenance Methods Of Dog Food Machine

- 2022-01-19 Operation Method Of Dog Food Machine Production Line

|

Demand table loading...

|