Nail Making Machine

Nail Making Machine

Nail Making Machine video

|

Demand table loading...

|

Nail Making Machine Description

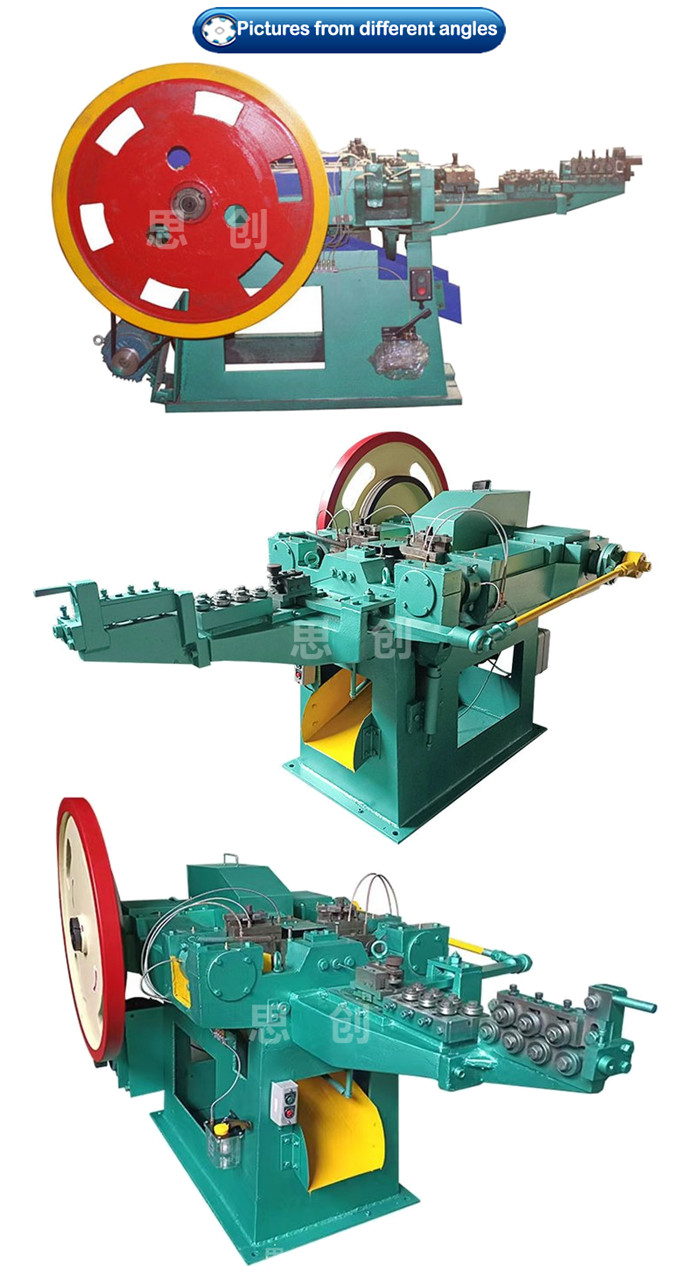

The full-automatic nail making machine is mainly used to manufacture yuan steel nails of various specifications. With a little modification, other special steel nails can be manufactured, such as oil blanket nails, V-shaped nails, U-shaped nails, corrugated nails, etc. The steel nails can be widely used in industry, construction, repair and other aspects. The main design of the machine refers to the design of similar high-precision products in West Germany, adopts the feedback of customers at home and abroad, and independently develops a new generation of automatic nail making machine based on the principle of favorable use and operation. The equipment has beautiful appearance, smooth lines and scientific and reasonable structure. The clearance adjustment of the central slider adopts wedge iron adjustment, which makes the operation and maintenance more convenient. The nail making machine has beautiful appearance, smooth lines and scientific and reasonable structure. The clearance adjustment of the central slider adopts wedge iron adjustment, which makes the operation and maintenance more convenient. The automatic oil supply system is adopted for lubrication, which makes the work more stable and reliable, greatly reduces the noise, greatly improves the working conditions and reduces the restrictions on the formulation of specifications for various models, It can effectively reduce the investment cost of investors. The nail making process is fully automated. Once started, it can continuously produce high-quality steel nails.

Four main operation steps of nail making machine:

1. Wire drawing: when making nails after purchase, it is necessary to determine what kind of reinforcement to use for nailing in the future, such as new reinforcement, waste reinforcement and so on. The wire drawing of waste reinforcement is troublesome, not as fast as that of new reinforcement, but the cost and profit of waste reinforcement is very objective. Finished wire drawing is fast and saves some manpower. The nailing speed is also very fast.

2. Nail making: after the wire is pulled, the adjusted semi-finished nails are produced through the full-automatic thread feeding machine head, and then the pulled wire is put into the thread feeding machine head.

3. Polishing: put the finished semi-finished nails into the polishing machine for polishing, and put some chemical raw materials such as sawdust, paraffin and gasoline into the polishing machine for friction and impact. Throw a shiny nail.

|

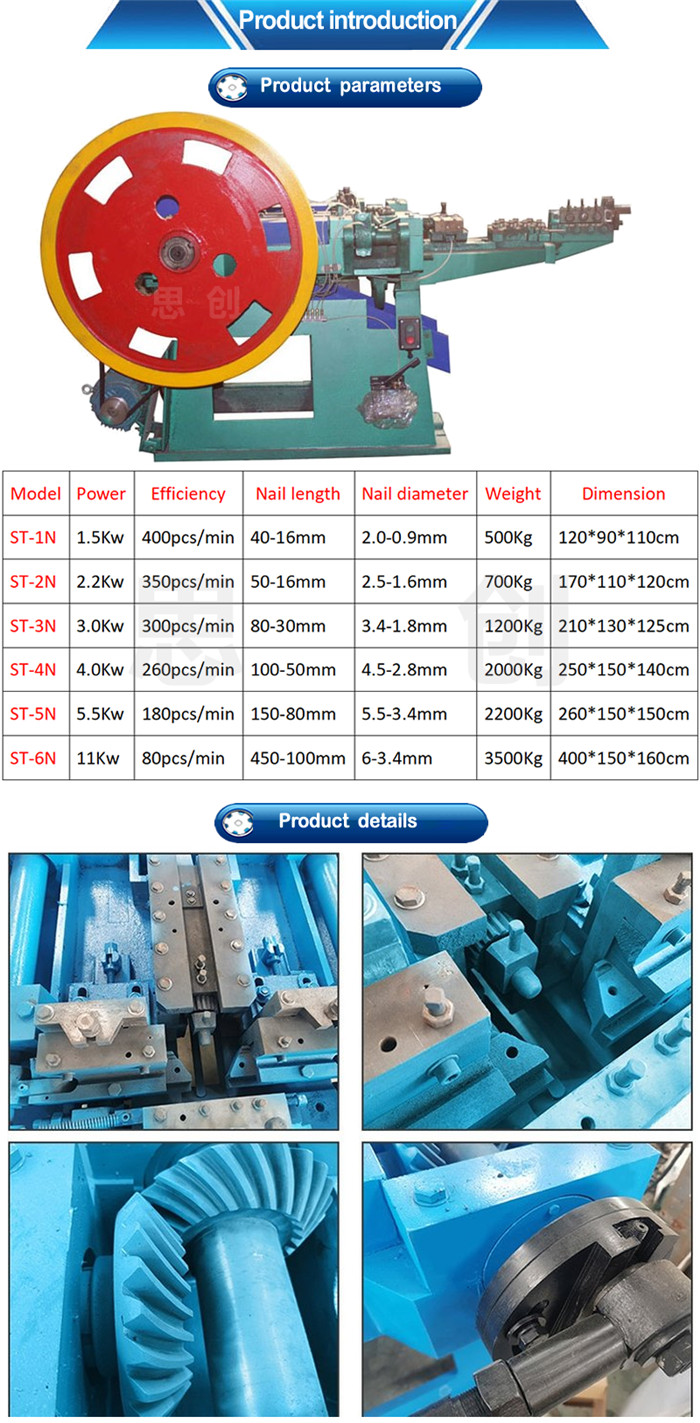

Model |

Power |

Efficiency |

Nail length |

Nail diameter |

Weight |

Dimension |

|

ST-1N |

1.5Kw |

400pcs/min |

40-16mm |

2.0-0.9mm |

500Kg |

120*90*110cm |

|

ST-2N |

2.2Kw |

350pcs/min |

50-16mm |

2.5-1.6mm |

700Kg |

170*110*120cm |

|

ST-3N |

3.0Kw |

300pcs/min |

80-30mm |

3.4-1.8mm |

1200Kg |

210*130*125cm |

|

ST-4N |

4.0Kw |

260pcs/min |

100-50mm |

4.5-2.8mm |

2000Kg |

250*150*140cm |

|

ST-5N |

5.5Kw |

180pcs/min |

150-80mm |

5.5-3.4mm |

2200Kg |

260*150*150cm |

|

ST-6N |

11Kw |

80pcs/min |

450-100mm |

6-3.4mm |

3500Kg |

400*150*160cm |

Nail Making Machine News

- 2023-01-27 What Is The Use Knowledge Of Nail Making Machine

- 2022-10-30 Processing Technology For Actual Operation Of Nail Making Machine

- 2022-08-20 Safety Operation Regulations For Nail Making Machine

- 2022-07-12 Nail-making Machine Operation Guide Video

- 2022-04-08 How To Use Nail Making Machine Correctly

- 2022-03-13 Four Main Operation Steps Of Nail Making Machine

- 2022-03-13 Operation Steps Of Nail Making Machine Made In China

- 2022-03-13 Screw Nail Making Machine Made In China At Best Price

|

Demand table loading...

|