Screw Tightening Machine

Screw Tightening Machine

Screw Tightening Machine video

|

Demand table loading...

|

Screw Tightening Machine Description

The full-automatic screw locking machine realizes the automatic transmission, tightening, detection and other processes of screws through various electric and pneumatic components, and simplifies the screw tightening process through equipment, so as to reduce the number of labor and reduce the adverse factors caused by manual misoperation. It is a typical non-standard automation equipment. Automatic screw locking machines are mainly divided into: hand-held screw locking machine, multi axis automatic screw locking machine and coordinate automatic screw locking machine. Automatic screw locking machine is mainly used for locking m1-m8 screws. Because it belongs to non-standard automation equipment and has customizable characteristics, products involving screw fastening can obtain corresponding solutions, and have a wide range of applications.

How to use the screw locking machine:

The use of automatic screw locking machine is relatively simple, that is, employees can place products, and the equipment automatically performs screw feeding, screw tightening, testing and other processes. Generally, there are the following steps:

1. Check the energization of ventilation and turn on the power switch and ventilation valve.

2. Check the driving stroke of all parts. The coordinate type also needs to program and control different products in advance and set the locking path.

3. Put in the products to be screwed and jog or inche them one by one, so as to check the accuracy of all work and the position of stroke.

4. Start up and test run, and check the effect and quality of the finished products, but after everything is stable, it can be safely used for production.

5. Conduct regular quality inspection and performance judgment.

Maintenance method of screw locking machine:

Due to the intelligence of machinery, although the manufacturer promises lifelong maintenance and repair, our own daily maintenance is also very important.

1. Keep it clean. When not in use, wipe it with a cloth with oil as much as possible and touch water as little as possible.

2. There shall be no debris and other tools left.

3. Keep ventilated and dry.

4. Regularly conduct plug-in ventilation and check the performance.

5. Check frequently to prevent rats from damaging the gas pipe and wire, which will affect future use.

Due to the intelligence and precision of its structure, please contact the manufacturer in time if you have any use problems or need maintenance. Do not disassemble it by yourself.

|

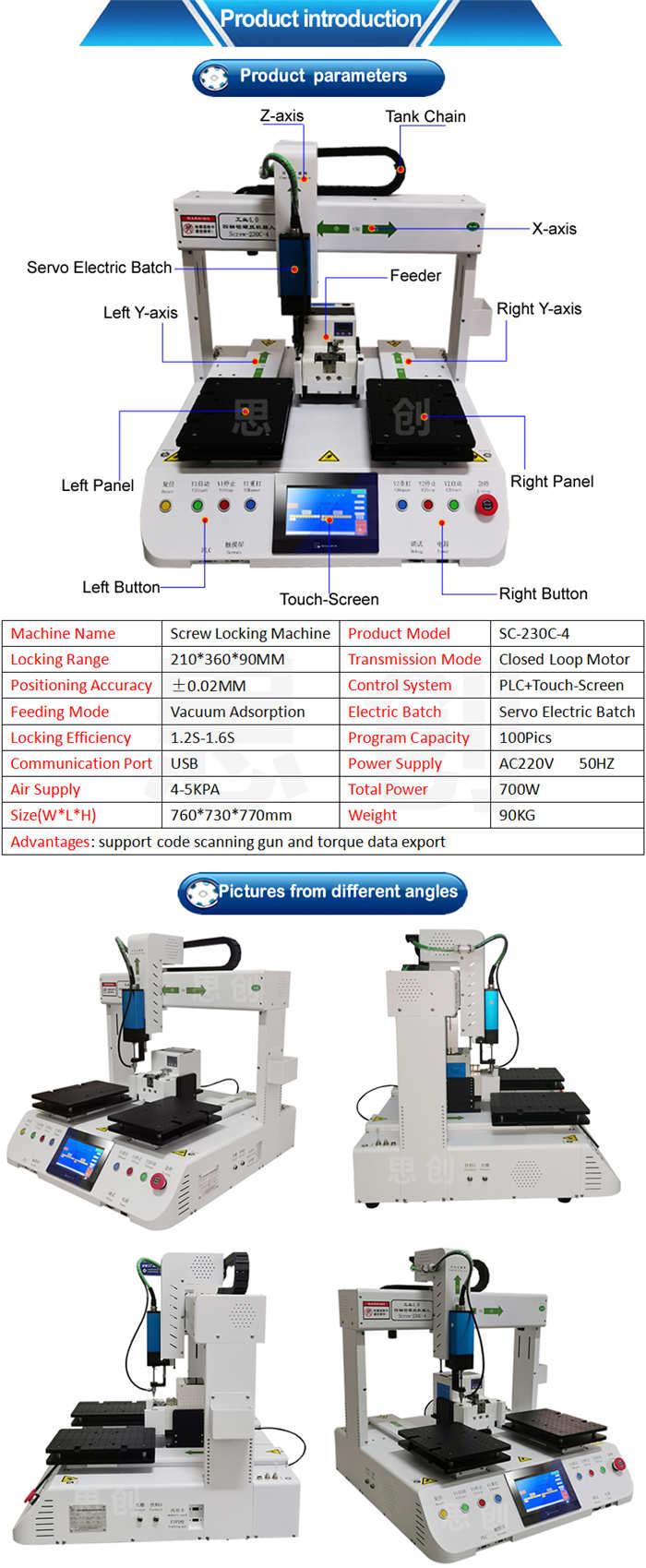

Machine Name |

Screw Locking Machine |

Product Model |

SC-230C-4 |

|

Locking Range |

210*360*90MM |

Transmission Mode |

Closed Loop Motor |

|

Positioning Accuracy |

±0.02MM |

Control System |

PLC+Touch-Screen |

|

Feeding Mode |

Vacuum Adsorption |

Electric Batch |

Servo Electric Batch |

|

Locking Efficiency |

1.2S-1.6S |

Program Capacity |

100Pics |

|

Communication Port |

USB |

Power Supply |

AC220V 50HZ |

|

Air Supply |

4-5KPA |

Total Power |

700W |

|

Size(W*L*H) |

760*730*770mm |

Weight |

90KG |

|

Advantages: support code scanning gun and torque data export |

|||

Screw Tightening Machine News

- 2022-11-14 Five Step Easy Operation Screw Locking Machine

- 2022-09-14 How To Operate Automatic Screw Locking Machine

- 2022-07-21 Operation Guide For Automatic Screw Locking Machine

- 2022-05-06 High Quality And Cheap Screw Locking Machine

- 2022-03-17 Maintenance method of screw locking machine

- 2022-03-17 How to use the screw tightening machine

- 2022-03-17 Working Principle Of Screw Locking Machine

|

Demand table loading...

|