Milling Machine

Milling Machine

Milling Machine video

|

Demand table loading...

|

Milling Machine Description

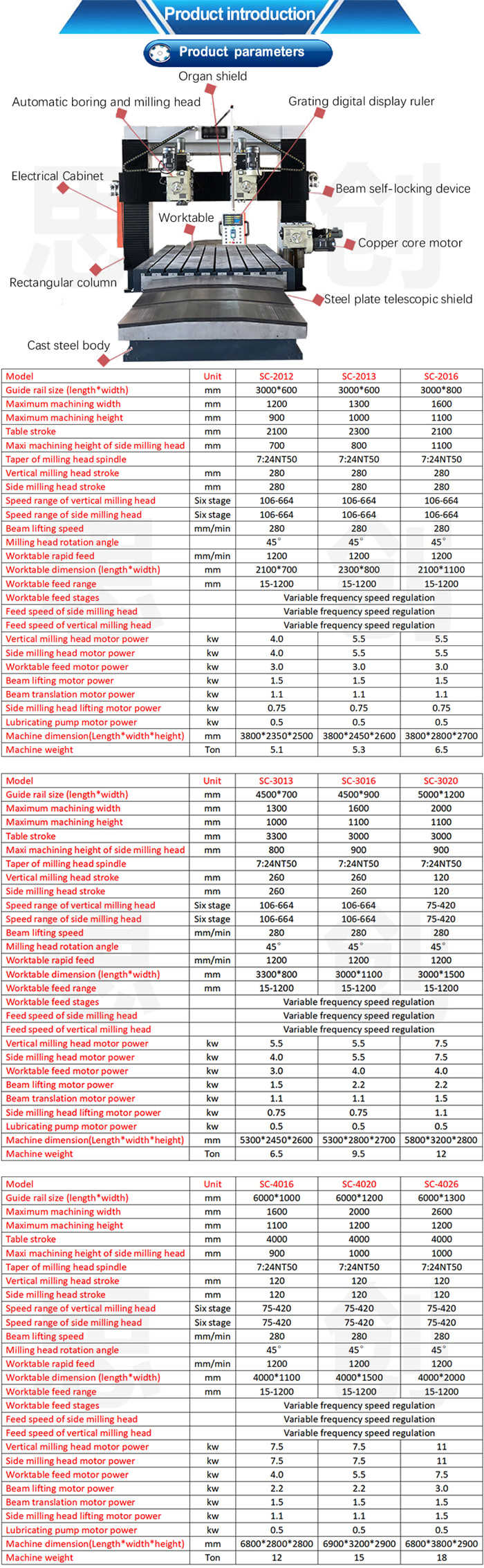

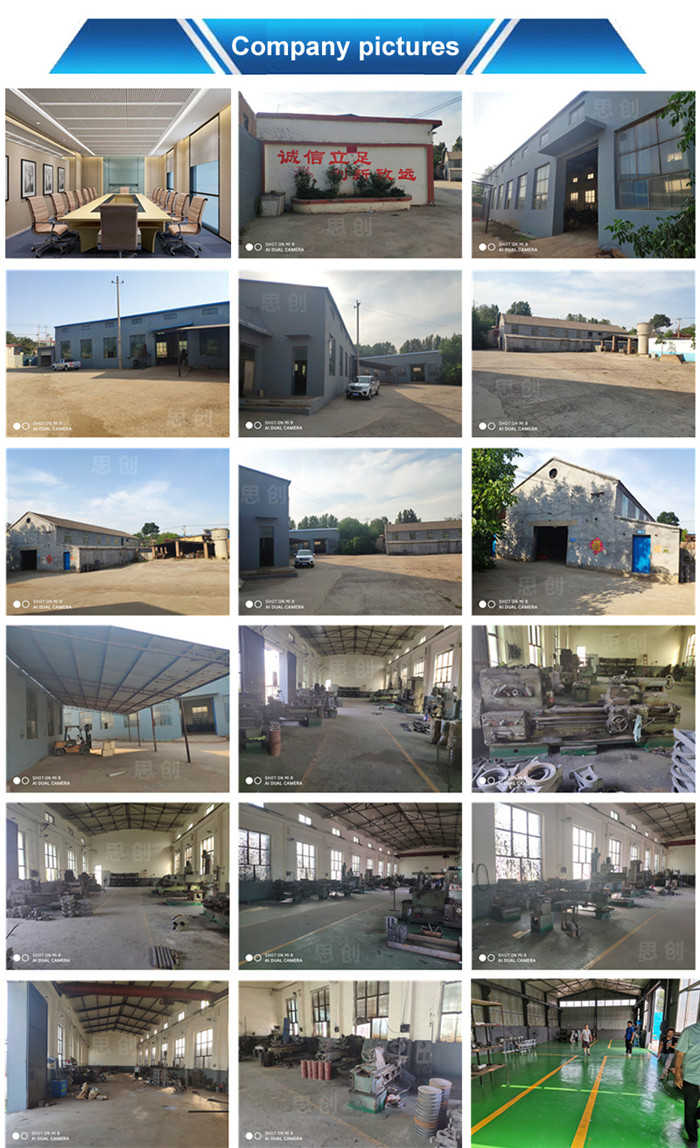

Gantry milling machine, referred to as gantry milling, is a milling machine with portal frame and horizontal long bed. The gantry milling machine can use multiple milling cutters to process the surface at the same time, with high machining accuracy and production efficiency. It is suitable for processing the plane and inclined plane of large workpieces in batch and mass production. CNC gantry milling machine can also process spatial curved surface and some special parts. Gantry milling machine is composed of portal frame, bed workbench and electrical control system. The portal frame is composed of columns and top beams, with beams in the middle. The beam can move up and down along the two column guide rails. There are 1 ~ 2 milling heads with vertical spindle on the beam, which can move laterally along the beam guide rail. A milling head with a horizontal spindle can also be installed on the two vertical columns, which can move up and down along the column guide rail. These milling heads can process several surfaces at the same time. Each milling head has a separate motor (up to 150 kW), speed change mechanism, control mechanism and spindle components A movable worktable is erected on the horizontal long bed and covered with a shield. During machining, the workpiece is installed on the worktable and moves longitudinally.

The gantry milling machine bed is equipped with an X-axis guide rail, and the gantry milling machine workbench is fastened on the bed. A gantry is erected on the movable span above the workbench, and the gantry also includes a gantry carriage, which is movably clamped on the x-axis guide rail. The z-axis guide rail is installed on the gantry. The beam is provided with a Z-axis carriage, the beam is movably clamped on the z-axis guide rail through the z-axis carriage, and the beam is also provided with a Y-axis guide rail. The milling device of the gantry milling machine is movably installed on the y-axis guide rail, so that the gantry can perform three-dimensional space milling of X, y and Z axes under the control of the NC circuit control system. The CNC gantry milling machine has high-precision operations such as milling, drilling, boring and cutting.

Safety operation procedures for CNC gantry milling machine:

1. Work objects shall be clamped with pressing plates, screws or special tools. It is not allowed to add casing when using ordinary wrench to avoid slipping and wounding people.

2. The tool must be clamped firmly, otherwise it is not allowed to drive.

3. Before operation, check the operation of the transmission part of the machine tool, and install the baffle of the machine tool before operation.

4. When milling various workpieces, especially rough milling, slow cutting shall be carried out at the beginning.

5. When moving the worktable and tool holder, loosen the fixing screws first.

6. When loading and unloading tools, use a copper hammer or wooden mallet to gently hit to prevent tool fragments from flying out and hurting people.

7. During cutting, it is not allowed to change speed and adjust the tool, and it is not allowed to touch or measure the workpiece by hand.

|

Model |

Unit |

SC-2012 |

SC-2013 |

SC-2016 |

|

Guide rail size (length*width) |

mm |

3000*600 |

3000*600 |

3000*800 |

|

Maximum machining width |

mm |

1200 |

1300 |

1600 |

|

Maximum machining height |

mm |

900 |

1000 |

1100 |

|

Table stroke |

mm |

2100 |

2300 |

2100 |

|

Maxi machining height of side milling head |

mm |

700 |

800 |

1100 |

|

Taper of milling head spindle |

|

7:24NT50 |

7:24NT50 |

7:24NT50 |

|

Vertical milling head stroke |

mm |

280 |

280 |

280 |

|

Side milling head stroke |

mm |

280 |

280 |

280 |

|

Speed range of vertical milling head |

Six stage |

106-664 |

106-664 |

106-664 |

|

Speed range of side milling head |

Six stage |

106-664 |

106-664 |

106-664 |

|

Beam lifting speed |

mm/min |

280 |

280 |

280 |

|

Milling head rotation angle |

|

45° |

45° |

45° |

|

Worktable rapid feed |

mm/min |

1200 |

1200 |

1200 |

|

Worktable dimension (length*width) |

mm |

2100*700 |

2300*800 |

2100*1100 |

|

Worktable feed range |

mm |

15-1200 |

15-1200 |

15-1200 |

|

Worktable feed stages |

|

Variable frequency speed regulation |

||

|

Feed speed of side milling head |

|

Variable frequency speed regulation |

||

|

Feed speed of vertical milling head |

|

Variable frequency speed regulation |

||

|

Vertical milling head motor power |

kw |

4.0 |

5.5 |

5.5 |

|

Side milling head motor power |

kw |

4.0 |

5.5 |

5.5 |

|

Worktable feed motor power |

kw |

3.0 |

3.0 |

3.0 |

|

Beam lifting motor power |

kw |

1.5 |

1.5 |

1.5 |

|

Beam translation motor power |

kw |

1.1 |

1.1 |

1.1 |

|

Side milling head lifting motor power |

kw |

0.75 |

0.75 |

0.75 |

|

Lubricating pump motor power |

kw |

0.5 |

0.5 |

0.5 |

|

Machine dimension(Length*width*height) |

mm |

3800*2350*2500 |

3800*2450*2600 |

3800*2800*2700 |

|

Machine weight |

Ton |

5.1 |

5.3 |

6.5 |

Milling Machine News

- 2022-11-11 Precautions During Operation Of Gantry Milling Machine

- 2022-09-11 Operating Procedures Of CNC Gantry Milling Machine

- 2022-07-19 CNC Planer Milling Machine Operation Guide

- 2022-05-03 Repair Method Of Gantry Milling Machine Guide Rail

- 2022-01-22 Tips For Purchasing Gantry Milling Machines In China

- 2022-01-13 Quotation Of Cnc Gantry Milling Machine

- 2021-12-17 Gantry Milling Machine Made In China At Best Price

- 2021-11-29 10% Off Today's Order For Gantry Milling Machine

- 2021-11-19 Milling Machine Is A Machine Tool With A Wide Range Of Uses

- 2021-11-08 Lubrication Method Of Gantry Milling Machine

- 2021-10-27 The Gantry Milling Machine Made In China Is Worth Buying

- 2021-10-21 Types And Introduction Of CNC Gantry Milling Machines

- 2021-10-21 Working Principle Of CNC Gantry Milling Machine

- 2021-10-21 Working Video Of CNC Gantry Type Milling Machine

- 2021-10-21 Operation Method And Steps Of CNC Gantry Milling Machine

- 2021-10-21 Structure Composition Of CNC Gantry Milling Machine

|

Demand table loading...

|