Thread Rolling Machine

Thread Rolling Machine

Thread Rolling Machine video

|

Demand table loading...

|

Thread Rolling Machine Description

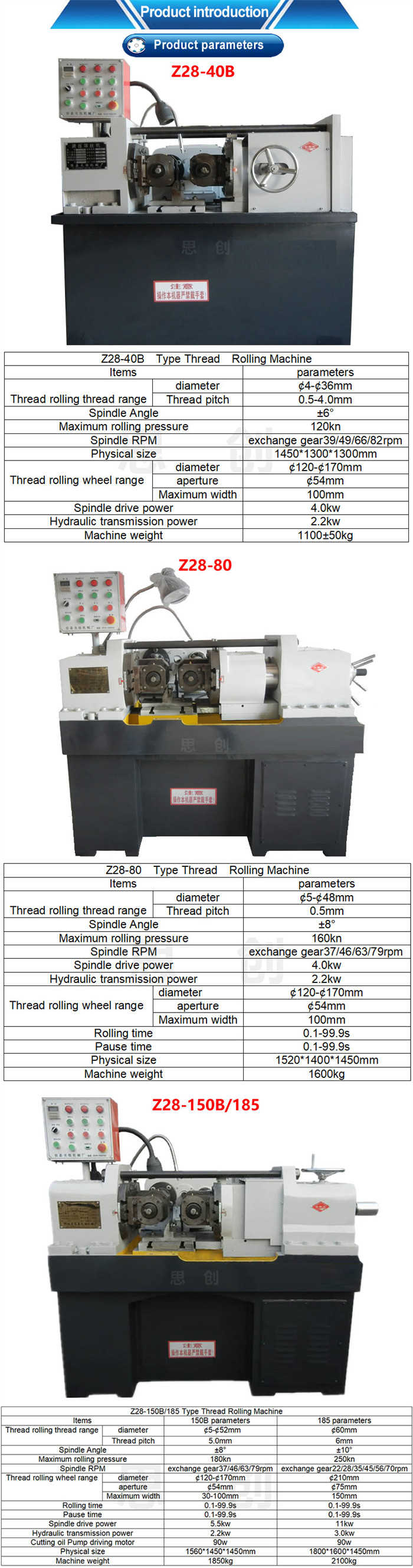

Thread rolling machine is a multi-functional cold extrusion machine tool. The thread rolling machine can roll the workpiece with thread, straight grain and twill in cold state within its rolling pressure range; Rolling of spur, helical and helical spline gears; Straightening, reducing, rolling and various forming rolling. The machine has a safe and reliable electro-hydraulic execution and control system, which can select each working cycle in manual, semi-automatic and automatic modes. thread rolling cold rolling process is an advanced non cutting process, which can effectively improve the internal and surface quality of the workpiece. The radial compressive stress generated during processing can significantly improve the fatigue strength and torsional strength of the workpiece. It is an ideal process with high efficiency, energy saving and low consumption. The thread rolling machine is suitable for rolling and forming straight lines, threads and twills with a diameter of 5-60mm in cold state. The anchor screws and wall threading threads can be processed by assembling the spiral thread rolling wheel. The hydraulic thread rolling machine adopts resin sand cast iron, with reasonable structure, simple operation and reliable quality. It is an ideal equipment for producing non-standard threads and standard parts (bolts).

Daily maintenance procedures for hydraulic thread rolling machine:

1. Keep the appearance of the thread rolling machine neat and clean without yellow robe, oil dirt and rust. Keep machine parts and main accessories complete and clean.

2. Keep the working site and pedal of the hydraulic thread rolling machine clean and tidy. Keep each guide rail surface and sliding surface clean and lubricated; Check whether the guide rail surface, worktable and sliding surface are damaged.

3. Keep all parts of the lubrication system of the thread rolling machine with sufficient oil, smooth oil circuit, eye-catching oil marks (Windows) and clean and complete lubrication appliances. Check all oil storage parts, lubrication parts and pipelines (including cooling system pipelines) for leakage.

4. Keep the electrical appliance, limit and interlocking device of thread rolling machine safe and reliable.

5. Timely maintain the equipment as required and make records. Fill in the desk hour record on time every month.

6. It is not allowed to change (make) equipment (including accessories) without permission.

7. Before work, check whether the rotating parts of the thread rolling machine are normal, whether the protective device is complete, whether there is excess on the working face, and add oil to each lubricating part. It can be operated only after confirming that there is no problem.

Thread Rolling Machine News

- 2022-09-10 How To Correctly Operate The Thread Rolling Machine

- 2022-07-19 Operation Rules Of Steel Straight Thread Rolling Machine

- 2022-05-02 What Does The Thread Rolling Machine Do For Us

- 2022-02-06 The Most Reliable Thread Rolling Machine Factory In China

- 2022-01-21 Price Of Thread Rolling Machine Made In China

- 2022-01-11 Working Principle Of Thread Rolling Machine

- 2021-12-14 Introduction Of Two Operation Modes Of Thread Rolling Machine

- 2021-11-28 Now Buy Thread Rolling Machine Free Accessories

- 2021-11-17 Processing Range Of Wire Rolling Machine

- 2021-11-07 Thread Rolling Machine Is Mainly Used For Cold Rolling Forming

- 2021-10-27 The Most Important Thing In The Wire Rolling Machine Industry

- 2021-10-21 Advantages Of New Three-axis Thread Rolling Machine

- 2021-10-13 Ways To Improve The Competitiveness Of Thread Rolling Machine Industry

- 2021-10-09 The Thread Rolling Machine Industry Is Greatly Affected By The Epidemic

- 2021-10-04 Lubricate All Parts Of The Thread Rolling Machine Before Operation

- 2021-09-30 The Thread Rolling Machine Made In China Has Low Price And High Quality

- 2021-09-26 Wire Rolling Machines Made In China Are Dealers In Mauritius

- 2021-09-20 Development Status Of Wire Rolling Machine Industry In China

- 2021-09-12 Lubricate All Parts Of The Thread Rolling Machine Before Operation

- 2021-09-09 The Machine That Makes Screws Is Called A Thread Rolling Machine

- 2021-09-06 Application Method Of Reinforcement Straight Thread Rolling Machine

- 2021-09-03 China's Automatic Thread Rolling Machine Is To Save Labor

- 2021-09-02 Switching Method Of Two Working Modes Of Thread Rolling Machine

- 2021-09-01 This Thread Rolling Machine Factory Is The Most Reliable In China

- 2021-08-31 Thread Rolling Machine Is Widely Used In Standard Parts Industry

|

Demand table loading...

|