CNC Lathe

CNC Lathe

CNC Lathe video

|

Demand table loading...

|

CNC Lathe Description

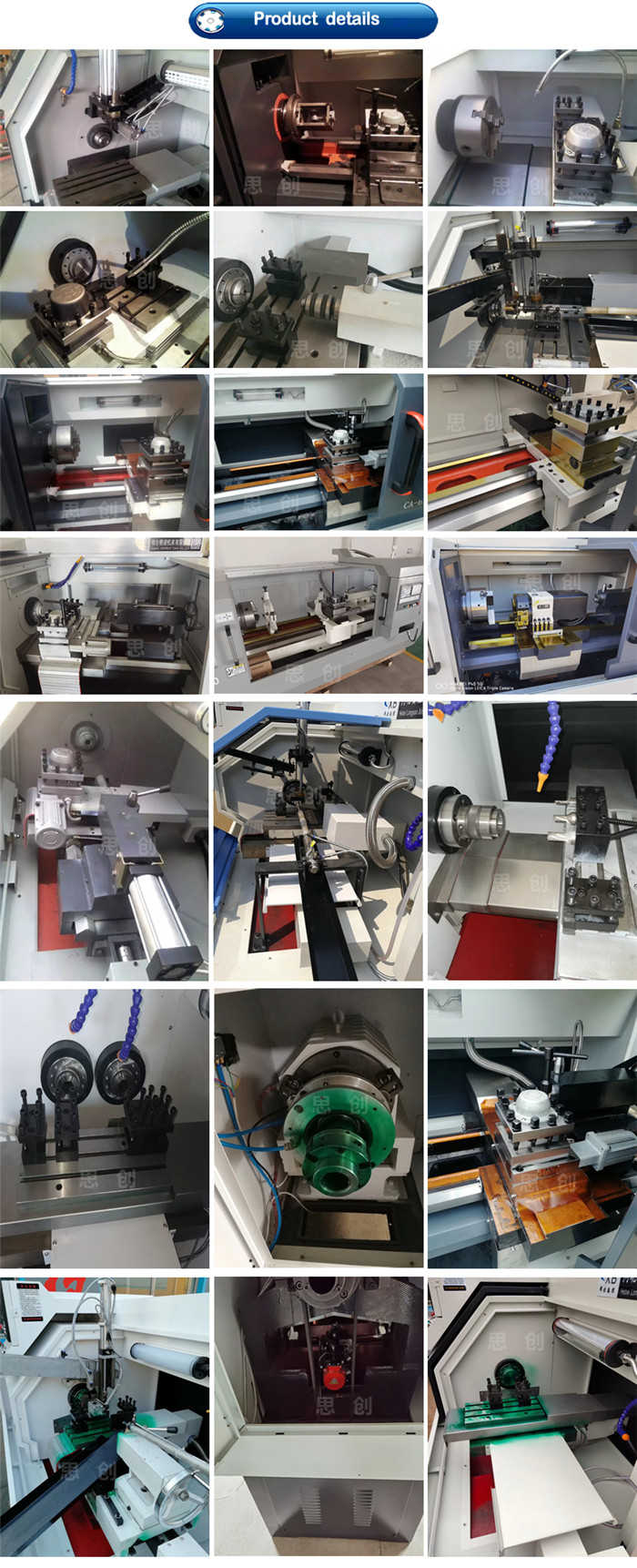

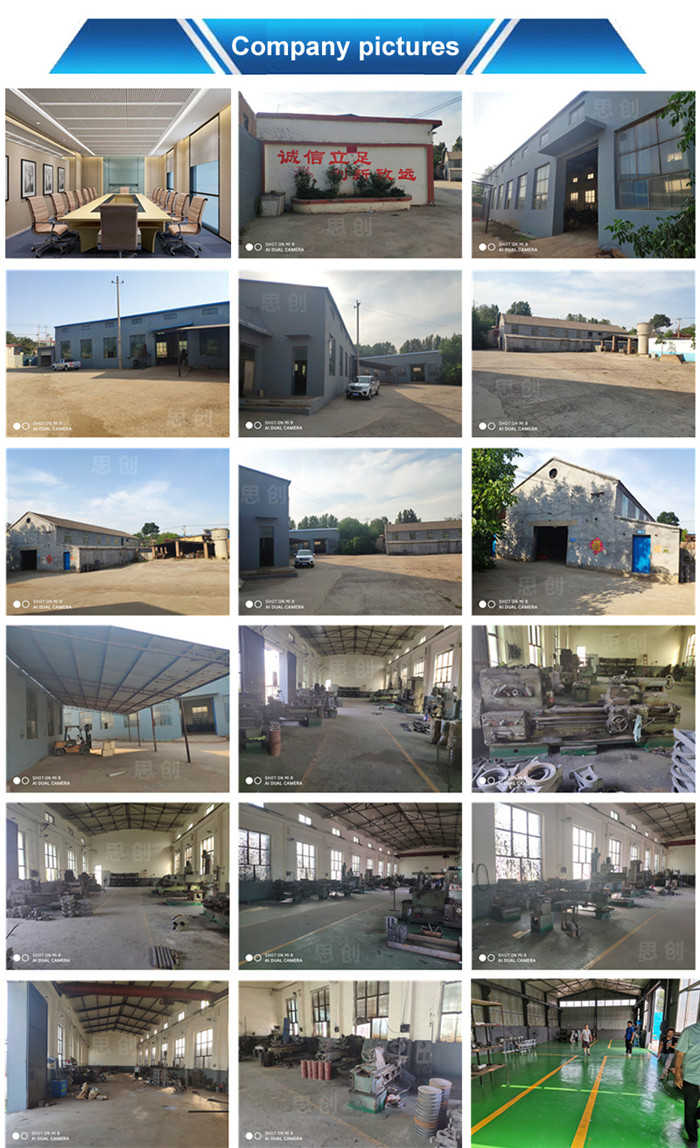

CNC instrument lathe is a simple CNC horizontal lathe. Generally speaking, most of the machine tools with the largest workpiece processing diameter of less than 250mm belong to instrument lathe. Instrument lathes are divided into ordinary type, hexagonal type, finishing type and automatic type. The lathe bed of CNC instrument lathe adopts the overall structure, resin sand modeling, and the guide rail adopts high-frequency quenching and grinding process, so that the machine tool has good wear resistance and precision retention. The stiffener makes the bed have excellent stiffness, vibration resistance and section distortion resistance. The bed guide rail is fully enclosed with telescopic steel plate protective cover, which effectively protects the service life of the guide rail from damage. CNC instrument lathes adopt spring collet for quick clamping, the motor directly drives the spindle, large and small discs for quick hand wrench operation, and vertical and horizontal positioning to control turning. Some instrument lathes are equipped with flange, tailstock device and die thread following device, which can process outer circle, inner circle, cutting, end face, cutting groove, turning taper, drilling, reaming, tapping, milling, grinding and other functions. It is widely used in the production and processing of small parts such as electrical appliances, fasteners, automobile and motorcycle accessories, instruments and meters, hardware and electrical appliances, cultural and educational supplies, film and television equipment, electromechanical products, plumbing fittings, valves, bearing rings, shafts and small workpieces such as glasses manufacturing. It is the most ideal high-efficiency equipment in the hardware machining industry.

Causes and solutions of spindle box heating of NC instrument lathe:

1. The spindle runs over speed for a long time and generates heat. Solution: adjust the bearing clearance, appropriately reduce the spindle speed (which shall not exceed the design maximum speed of the machine tool), and apply high-speed grease on the bearing.

2. The main shaft bearing clearance is too tight and generates heat. Solution: refer to section 4 to adjust the bearing clearance of the main shaft.

3. The main shaft bearing is rusted, worn and heated, and parts of the main shaft may be worn or rusted after long-term fatigue use or in humid environment; Long storage time without use will also cause bearing rust. Solution: clean the bearing, adjust the grease or replace the bearing.

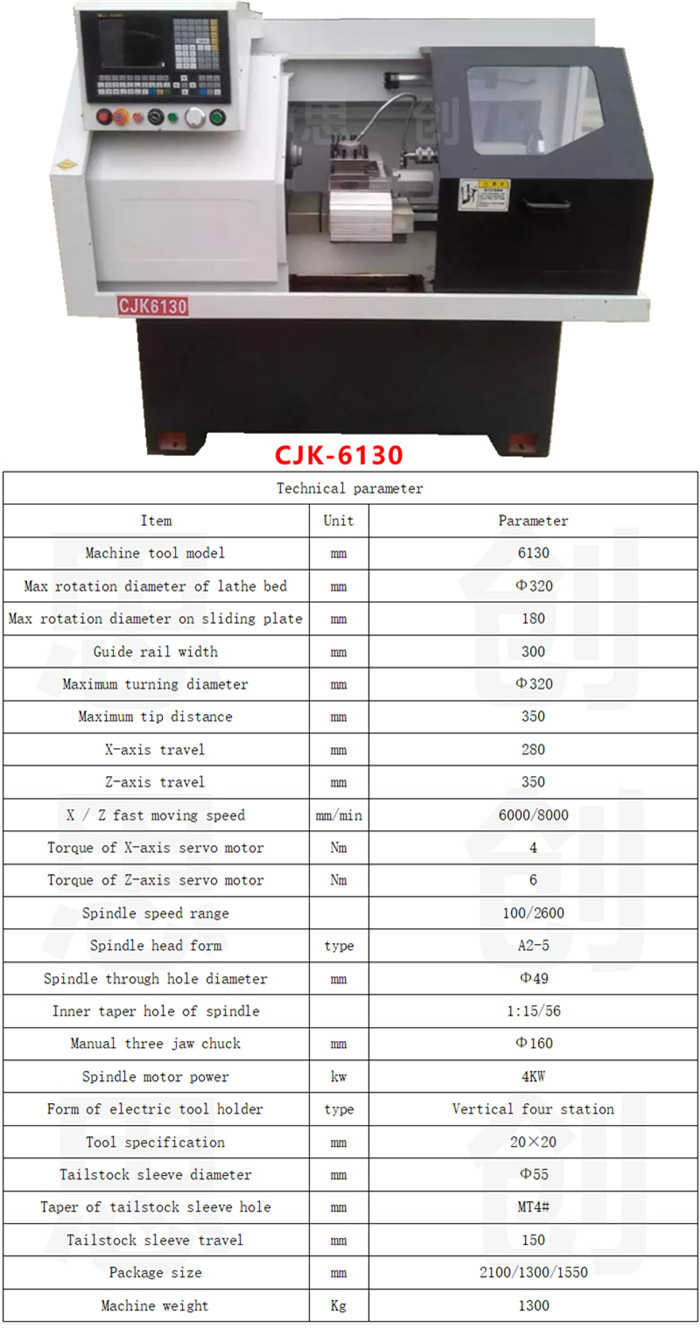

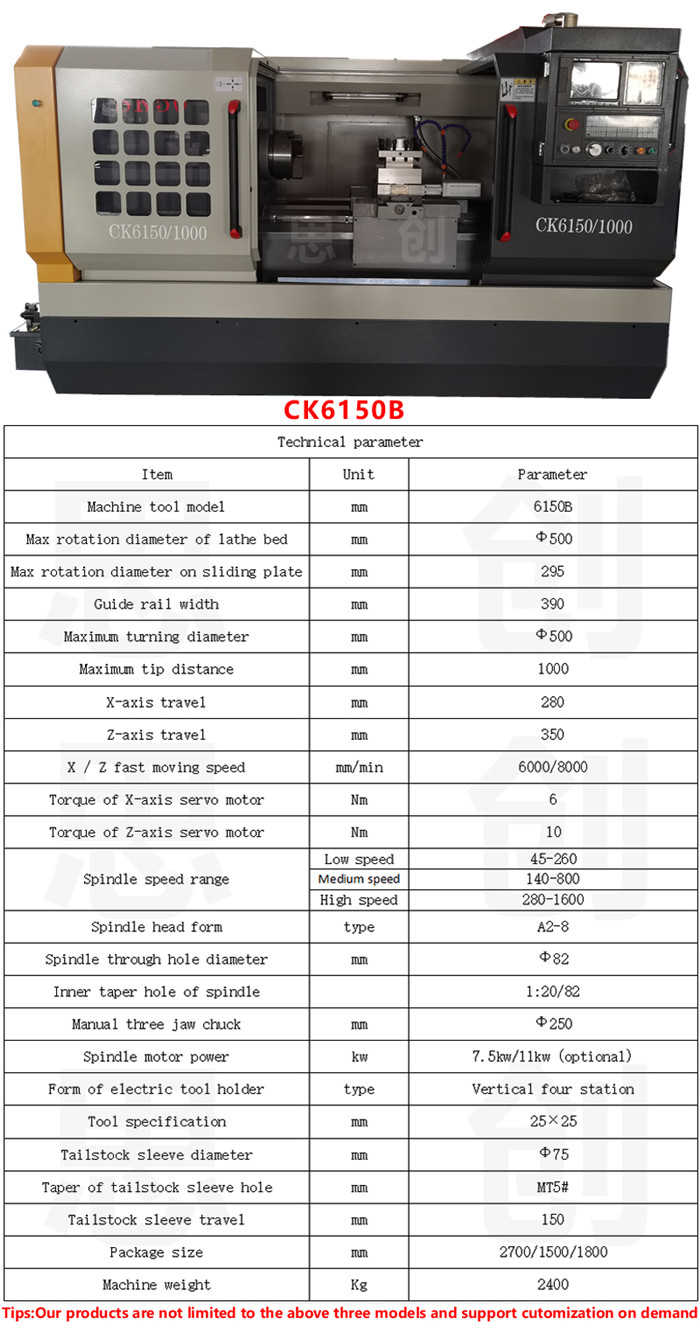

Technical parameter | ||||

Item | Unit | Parameter | ||

Machine tool model | mm | 0640 | 6130 | 6150B |

Max rotation diameter of lathe bed | mm | Φ260 | Φ320 | Φ500 |

Max rotation diameter on sliding plate | mm | 105 | 180 | 295 |

Guide rail width | mm | 260 | 300 | 390 |

Maximum turning diameter | mm |

| Φ320 | Φ500 |

Maximum tip distance | mm |

| 350 | 1000 |

X-axis travel | mm | 280 | 280 | 280 |

Z-axis travel | mm | 200 | 350 | 350 |

X / Z fast moving speed | mm/min | 6000/8000 | 6000/8000 | 6000/8000 |

Torque of X-axis servo motor | Nm | 4 | 4 | 6 |

Torque of Z-axis servo motor | Nm | 4 | 6 | 10 |

Spindle speed range | Low speed | 100/2600 | 100/2600 | 45-260 |

Medium speed | 140-800 | |||

High speed | 280-1600 | |||

Spindle head form | type | A2-5 | A2-5 | A2-8 |

Spindle through hole diameter | mm | 49 | 49 | Φ82 |

Inner taper hole of spindle |

| 1:15/56 | 1:15/56 | 1:20/82 |

Manual three jaw chuck | mm | Φ160 | Φ160 | Φ250 |

Spindle motor power | kw | 3kw | 4kw | 7.5kw/11kw (optional) |

Form of electric tool holder | type |

| Vertical four station | |

Tool specification | mm | 20×20 | 20×20 | 25×25 |

Tailstock sleeve diameter | mm |

| Φ55 | Φ75 |

Taper of tailstock sleeve hole | mm |

| MT4# | MT5# |

Tailstock sleeve travel | mm |

| 150 | 150 |

Package size | cm | 150/110/155 | 210/130/155 | 270/150/180 |

Machine weight | Kg | 900 | 1300 | 2400 |

CNC Lathe News

- 2022-11-10 Beginner's Guide to CNC Machine Tools

- 2022-09-11 Basic Operation Tutorial And Steps Of CNC Lathe

- 2022-07-19 Guide To Operation Of CNC Lathes Made In China

- 2022-05-03 Basic Rules For Instrument CNC Lathe Processing

- 2022-01-22 Skills Of Purchasing Chinese CNC Lathes

- 2022-01-13 Price Of Cnc Lathes Made In China

- 2021-12-16 Small Cnc Lathe Made In China At Best Price

- 2021-11-29 Development Trend Of CNC Lathe

- 2021-11-19 Cnc Lathes Made In China Have Stable Performance And Low Price

- 2021-11-08 Quotation For Small CNC Lathes Made In China

- 2021-10-27 The Failure Rate Of Cnc Lathes Made In China Is Very Low

- 2021-10-21 The Basic Knowledge And Information Of Cnc Lathe Bearings

- 2021-10-13 Operation Method And Troubleshooting Of Mini Cnc Lathe

- 2021-10-09 CNC Lathes Made In China Have The Highest Cost Performance

- 2021-10-07 Common Faults And Solutions Of Spindle Of Mini Cnc Lathe

- 2021-10-07 Common Faults And Solutions Of Small Cnc Lathe

- 2021-10-07 Cnc Instrument Lathes Belong To Simple Horizontal Lathes

- 2021-10-07 Structure And Working Principle Of Mini Cnc Lathe

|

Demand table loading...

|