Juicer

Juicer

Juicer video

|

Demand table loading...

|

Juicer Description

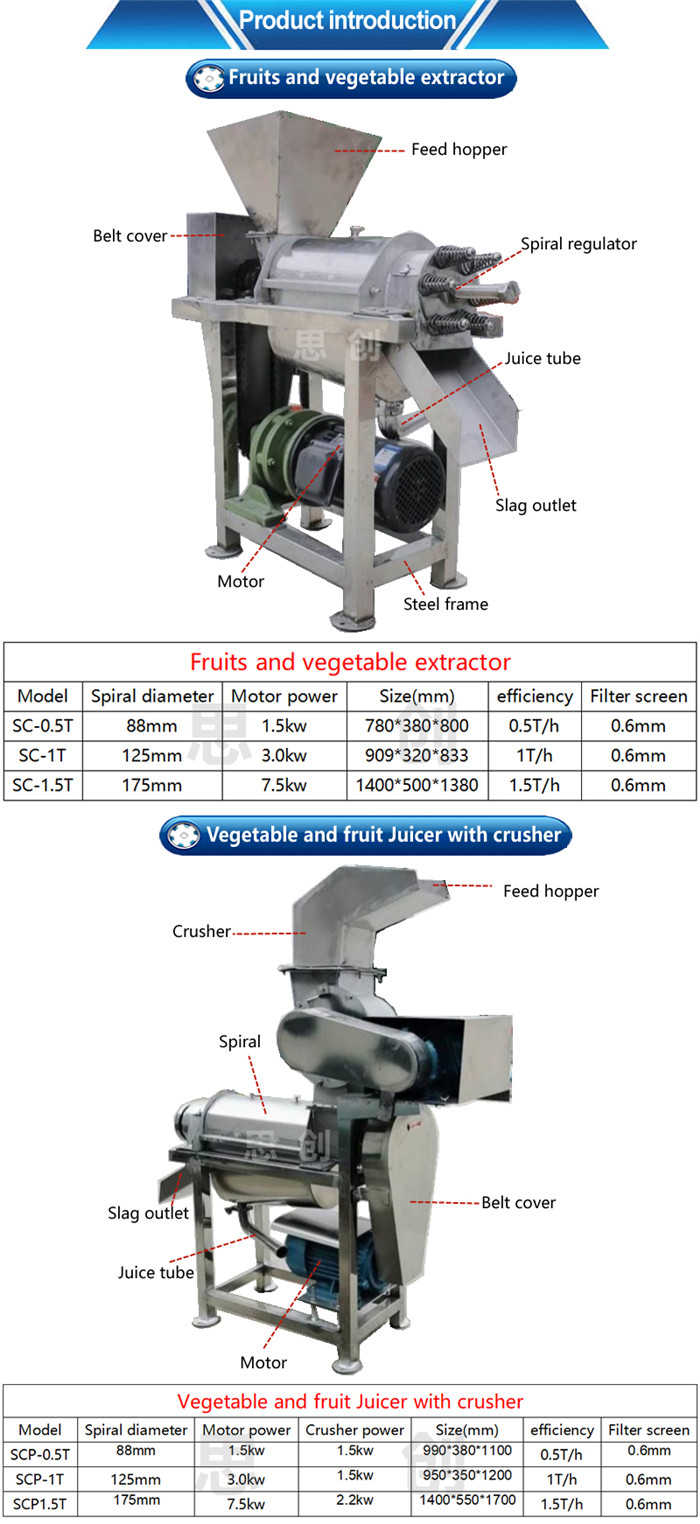

Structure of commercial screw Juicer:

The industrial juicer is composed of front support, feed hopper, crushing, screw, filter screen, juice container, rear support, slag chute and other parts. The left end of the spiral main shaft is supported in the rolling bearing seat and the right end is supported in the hand wheel bearing seat. The motor drives the screw through a pair of triangular pulleys. The tripod is installed on the main shaft, the beating plate is installed on the tripod, and the screen, funnel and slag are installed on the lower bracket. The inner cylinder and feed hopper are loaded on the bracket, and the whole upper bracket is hinged, which can be opened to check the quality of fruit pulp.

Working principle of fruit and vegetable juicer:

The main component of the double screw juicer is that the bottom diameter of the screw increases gradually along the direction of the slag outlet and the pitch decreases gradually. When the material is pushed by the screw, the material is pressed due to the reduction of the volume of the screw cavity. The rotation direction of the screw spindle is clockwise when viewed from the feed hopper to the slag chute. The raw material is added into the feed hopper and pressed under the propulsion of the screw. The pressed juice flows into the juice container at the bottom through the filter screen, while the waste is discharged through the annular gap formed between the screw and the conical part of the pressure regulating head. The size of the gap can be adjusted by the movement of the pressure regulating head along the axial direction. It is used clockwise (when the bearing seat of the hand wheel is rotated from the slag discharge tank of the equipment to the feed hopper end, the pressure regulating head will turn to the left, and the gap will be reduced; otherwise, the gap will become larger.) Change the size of the gap, that is, adjust the resistance of slag discharge. The slag yield can be changed. However, if the gap is too small, some slag particles will be extruded through the filter screen together with the juice under strong extrusion. Although the juice output increases, the quality of the juice decreases relatively. The size of the gap should depend on the specific process requirements of the user. Stainless steel spiral fruit and vegetable juicer is suitable for beating and separating a variety of fresh fruits and vegetables. Products such as orange meat, grapes, mulberry, red bayberry and honey peach (de nucleated) can be used to achieve fruit sauce, separate fruit stones, fruit seeds and thin skin, and green vegetables (cut) tomato, pepper and celery (cut) can also be used to achieve vegetable juice and separate vegetable tendons. It is an ideal machine for making jam, fruit juice and vegetable juice and an important equipment for food processing enterprises.

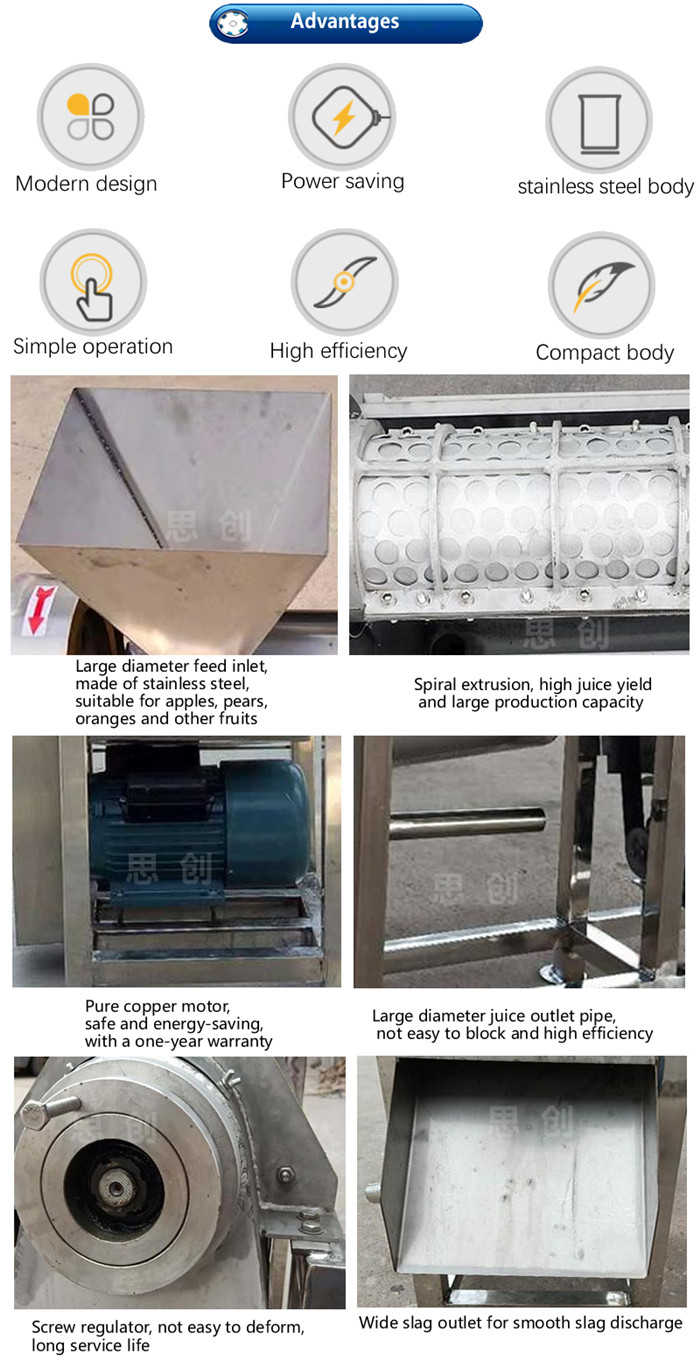

Uses and advantages of fruit Juicer:

1. It is used to press pineapple, apple, pear and other fruits.

2. Used for pressing mulberry, grape, orange, orange and other berries.

3. It is used to press tomatoes, ginger, garlic, celery and other vegetables.

4. Spiral extrusion, high pressure, high efficiency and sufficient juicing.

5. Fully automatic juicing and slag removal of berries, kernel fruits and vegetables.

6. The part in contact with materials is made of national standard 304 stainless steel.

7. The frame material can be national standard 304 stainless steel, depending on the customer's requirements.

|

Fruits and vegetable extractor |

|||||

|

Model |

Spiral diameter |

Motor power |

Size(mm) |

efficiency |

Filter screen |

|

SC-0.5T |

88mm |

1.5kw |

780*380*800 |

0.5T/h |

0.6mm |

|

SC-1T |

125mm |

3.0kw |

909*320*833 |

1T/h |

0.6mm |

|

SC-1.5T |

175mm |

7.5kw |

1400*500*1380 |

1.5T/h |

0.6mm |

|

Vegetable and fruit Juicer with crusher |

||||||

|

Model |

Spiral diameter |

Motor power |

Crusher power |

Size(cm) |

efficiency |

Filter screen |

|

SCP-0.5T |

88mm |

1.5kw |

1.5kw |

99*38*110 |

0.5T/h |

0.6mm |

|

SCP-1T |

125mm |

3.0kw |

1.5kw |

95*35*120 |

1T/h |

0.6mm |

|

SCP1.5T |

175mm |

7.5kw |

2.2kw |

140*55*170 |

1.5T/h |

0.6mm |

Juicer News

- 2023-01-13 Daily Maintenance Of Commercial Juicer

- 2022-10-26 There Are Mainly Two Types Of Consumer Groups Of Juicer

- 2022-08-16 Operation Guide Of Commercial Juicer

- 2022-07-08 Precautions For The Operation Of Fruit And Vegetable Juicer

- 2022-04-05 How To Operate The Fruit And Vegetable Juicer

- 2022-01-29 The Price Of Juicer In China Surprised Me

- 2022-01-19 Price Of Commercial Juicers Made In China

- 2021-12-30 Structure And Working Principle Of Screw Juicer

- 2021-12-09 Working Principle Of Screw Juicer Made In China

- 2021-11-26 Commercial Juicer Sample Is For Free Only Today

- 2021-11-13 Quotation Of Screw Juicer Made In China

- 2021-11-03 Product Advantages And Application Scope Of Screw Juicer

- 2021-10-25 Equipment Structure And Working Principle Of Juicer

- 2021-10-17 Working Principle Of Fruit And Vegetable Juicer Machine

- 2021-10-12 The Screw Juicer Is A Slag Juice Separation Equipment

- 2021-10-08 Structure And Composition Of Fruit And Vegetable Juicer

- 2021-10-03 Working Video And Operation Method Of Fruit And Vegetable Juicer

- 2021-09-30 Juicer Is Widely Used In Vegetable And Fruit Industry

- 2021-09-26 Working Principle Of Vegetable And Fruit Juicing Machine

- 2021-09-26 The Fruit And Vegetable Juicer Made In China Has High Efficiency And Low Price

- 2021-09-26 List Of Distributors Of Commercial Juicers Made In China In Mauritius

|

Demand table loading...

|