Spaghetti Machine

Spaghetti Machine

Spaghetti Machine video

|

Demand table loading...

|

Spaghetti Machine Description

Specific operation steps of spaghetti machine:

1. Power on test run: first remove the template and V-belt, and then connect the power for inching. After determining the rotation direction of the motor (as indicated by the arrow), install the V-belt and close it for test run for one minute, and then install the template. If the steering connection is reversed, there is a risk of damaging the formwork.

2. Machine inspection: before starting the machine, check whether the parts are normal, whether the screws are loose, and the grounding wire must be installed.

3. Adjust the machine head: adjust the position before and after shutdown, loosen the column sleeve brake screw, which can swing the machine head back and forth, and adjust the high and low position: after the column sleeve brake screw is loose, slowly loosen the retaining ring and fixed screw, which can adjust the machine head up and down.

4. Formwork removal: first pay attention to the rotation direction, which shall be the same as that of the grooved wheel, and twist it with force. If it cannot be twisted by hand, it can be pulled with a wrench.

5. Remove the cover template: first loosen the screws and open the cover plate by hand to adjust the tightness of the triangular belt.

6. Dough blending: mix the standard powder with cold water and synthesize the dough similar to the soft and hard of sliced noodles and hand pulled noodles, knead it away from your hands, cut it into appropriate small pieces, roll dry flour for use (other edible flour and coarse grain flour can also be used). If you can't knead it, there will be phenomena such as dough paste mouth, auger, and noodles sticking teeth.

7. Feeding operation: start up and test run for one minute, which can be used for feeding and pressing the noodles. Put the mixed noodles to be used into the feeding port one after another. Pour the noodles extruded by the auger into the boiling pot. After pressing, shovel the remaining noodles from the bottom of the mold with a small shovel. If they are stuck, they shall be stirred and separated with the water in time.

8 washing and cleaning: remove the formwork and remove the winch. Disassembly of the auger: clamp it with a wooden stick, and the auger will not rotate. Move the grooved wheel with a hand board to rotate in the opposite direction, then the auger will be removed slowly, otherwise it will be screwed on.

9. Maintenance and rust prevention: after cleaning, apply edible oil to the connecting hole of the auger. Align the auger with the main shaft and rotate the grooved wheel according to the Steering requirements. Since the auger can be reset, align the notch with the pin and knock the bottom of the auger with a hammer. After cleaning, apply edible oil on the wire mouth of the formwork and the cylinder, and add oil to each rotating part at intervals to make the rotation flexible and prevent corrosion.

10. Adjust the triangular belt: when the triangular belt slips or is too tight, loosen the four screws on the left and right at the tail of the formwork beam to adjust the distance between the two.

Precautions for using spaghetti machine:

1. Don't soak in water or let the noodle machine touch water!

2. Don't add salt to the noodle formula, otherwise the machine will rust!

3. Clean the noodle machine, wipe it with kitchen paper, brush, toothpick, small stick, etc. are good tools.

|

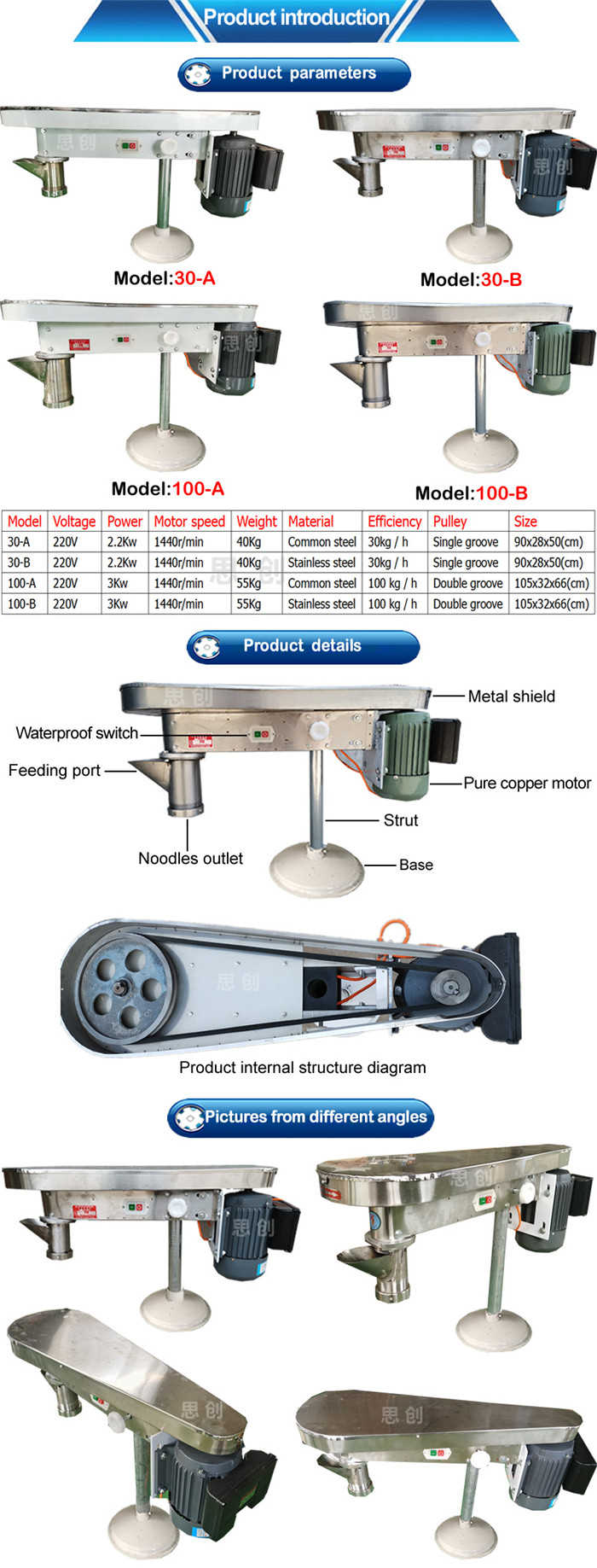

Model |

Voltage |

Power |

Motor speed |

Weight |

Material |

Efficiency |

Pulley |

Size |

|

30-A |

220V |

2.2Kw |

1440r/min |

40Kg |

Common steel |

30kg / h |

Single groove |

90x28x50(cm) |

|

30-B |

220V |

2.2Kw |

1440r/min |

40Kg |

Stainless steel |

30kg / h |

Single groove |

90x28x50(cm) |

|

100-A |

220V |

3Kw |

1440r/min |

55Kg |

Common steel |

100 kg / h |

Double groove |

105x32x66(cm) |

|

100-B |

220V |

3Kw |

1440r/min |

55Kg |

Stainless steel |

100 kg / h |

Double groove |

105x32x66(cm) |

Spaghetti Machine News

- 2022-12-22 This Manufacturer's Spaghetti Machine Is Easy To Use And Cheap

- 2022-10-22 How To Replace The Spaghetti Machine Triangle Belt

- 2022-08-11 Operation Guide For Spaghetti Machine Made In China

- 2022-05-22 The Price Of Spaghetti Machine Is The Lowest Here

- 2022-04-03 Operation Steps Of Spaghetti Machine Made In China

- 2022-01-26 Chinese Spaghetti Machine Year-end Promotion

- 2022-01-17 Price Of Spaghetti Machine Made In China

- 2021-12-23 Spaghetti Machine Made In China At Best Price

- 2021-12-04 What Is The Main Content Of Spaghetti Machine Maintenance

- 2021-11-24 The Spaghetti Machine Must Be Installed On A Flat

- 2021-11-11 Advantages Of Spaghetti Machine Made In China

- 2021-10-30 Quotation Of Spaghetti Machine Made In China

- 2021-10-24 Spaghetti Machine Must Be Operated In A Standardized Manner

- 2021-10-16 Daily Maintenance Method Of Spaghetti Machine

- 2021-10-11 The Output Of Spaghetti Machines Made In China Is Really High

- 2021-10-07 The Spaghetti Machine Made In China Has The Highest Cost Performance

- 2021-10-02 Working Video And Working Principle Of Spaghetti Machine

- 2021-09-29 Contact Information Of Spaghetti Machine Dealer In Mauritius

- 2021-09-22 The Reasons Of Spaghetti Machines Replacing Manual Production

- 2021-09-18 The Most Easy To Operate Spaghetti Machine Made In China

- 2021-09-11 The Spaghetti Machine Fully Maintains The Noodle Tendons

- 2021-09-07 Operating Skills Of Automatic Spaghetti Machine

- 2021-09-06 You Must Have Never Seen This Spaghetti Machine From China

- 2021-09-03 Quality Inspection Standard Of Spaghetti Machine

- 2021-09-02 Method And Steps For Cleaning Spaghetti Machine

|

Demand table loading...

|